Precision-Engineered Compensator Solutions for High-Torque Harley Primary Systems

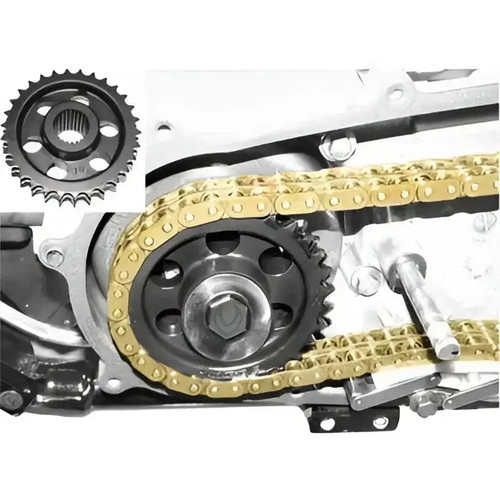

A Harley compensator sprocket plays a critical role in smoothing crankshaft power before it reaches the clutch basket. In modern Harley drivetrains, the Harley compensator drive absorbs rotational shock created by large-displacement engines, protecting internal components from harsh engagement and shutdown noise. Over time, worn Harley compensators cause clunking, vibration, and accelerated primary wear. This is why riders working with V-Twin compensator parts focus on material quality, oil distribution, and load control rather than appearance alone.

Purpose-built upgrades presented by TMF Cycles such as the Baker Compensator Sprocket address long-standing durability issues through controlled oil scavenging, reduced cam lobe velocity, and optimized mass placement. Riders choosing V-Twin compensator parts replacement often compare this approach with solid options like the Drag Compensator Eliminator, which removes spring mechanisms entirely for quieter operation. Supporting components like the Cycle-Rama Compensator Ramp add impact resistance through hardened chromium alloy steel. Together, these solutions define how a V-Twin primary compensator should manage torque pulses. Compared with typical aftermarket motorcycle compensators, these designs rely on structural geometry instead of band-aid fixes. Heat-treated alloys, billet machining, and spoke-supported hubs form the backbone of modern billet compensator parts, whether used in a complete compensator kit motorcycle setup or individual motorcycle compensator assemblies designed to stabilize the motorcycle compensator hub under repeated load cycles. The result is quieter starts, reduced wear, and longer-lasting motorcycle compensators built for real riding conditions.

FAQs

What problem does the Baker Compensator Sprocket specifically solve?

It reduces cam lobe velocity, distributes oil using centrifugal force, and minimizes noise while maintaining the stock 34-tooth primary ratio.

How does a compensator eliminator differ from a traditional compensator?

A solid eliminator removes springs entirely, reducing moving parts, lowering noise, and eliminating the need for a full compensator assembly.

Why does material choice matter in compensator ramps?

Case-hardened chromium alloy steel resists impact and fatigue, preventing fractures under repeated torque pulses.

When should a rider consider replacing compensator components?

Noticeable clunking, vibration during startup, or accelerated primary wear usually indicates internal compensator wear requiring attention.